Sustainability goals are driving a transformative shift to New Energy Vehicles (NEVs) and electrification in the automotive industry. This shift is creating unprecedented disruption – new entrants and industry stalwarts are upending everything from design concepts to manufacturing approaches. Given the scope of these disruptions, the need for pioneering solutions to address automotive industry challenges has never been greater.

ITW Automotive, with a long history of customer-driven innovation, is committed to remaining at the forefront of this transformation by leveraging its deep industry knowledge, collaborative approach, and focus on outcomes-driven innovation for its customers. In 2021, ITW founded the ITW Automotive NEV Intelligent Mobility Center (NIMC) to identify and enable high-value opportunities in systems critical to and more sustainable and electrified future.

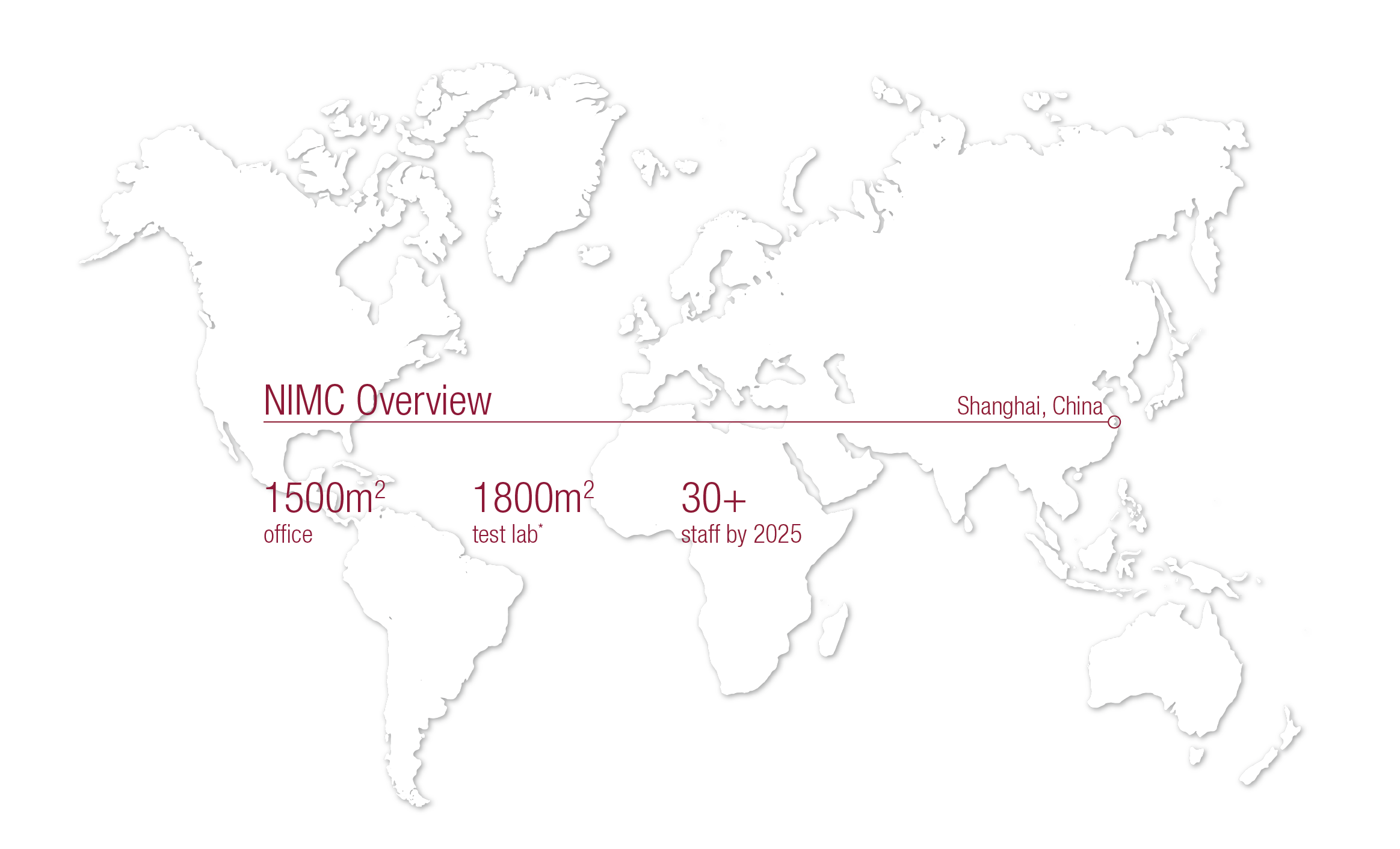

The NIMC, located in the Minhag district of Shanghai, China, is a modern research and development facility focused on application areas critical to electrification, specifically, thermal management and smart components.

The unprecedented rate of change in the industry requires a combination of speed and simplicity to win. The NIMC is meets this challenge by leveraging ITW’s proprietary 80/20 Front-to-Back Process to minimize complexity with a platformization and modularization approach to innovation and product development.

The NIMC employs a comprehensive approach to address its objectives. Leveraging their extensive systems engineering expertise, the NIMC team actively assesses the potential impact of emerging trends and technologies on overall vehicle performance. Armed with this understanding, they utilize their deep component design knowledge to develop prototype solutions and collaborate with customers to address emerging challenges and pain-points, with a particular focus on medium- and long-term trends. This unique blend of expertise and cutting-edge facilities enables the NIMC to establish and maintain partnerships with leading OEM/Tier advanced technology and engineering organizations, fostering the collaborative development of innovative and forward-thinking products. By adopting a results-oriented philosophy, the NIMC also evaluates long-term market trends, enabling them to prioritize key areas that yield significant improvements in system performance, while avoiding solutions that do not contribute substantially to overall vehicle characteristics such as range, efficiency, and ease of manufacturing.

One of the NIMC’s primary responsibilities is to develop and maintain a dynamic set of Thermal Technology Roadmaps and Technology Trend Impact Assessments. These deliverables play a crucial role in identifying the evolving technologies within the electric vehicle (EV) market and prioritizing high-impact trends, along with their associated uncertainties. By establishing these roadmaps and impact assessments, the NIMC lays the groundwork for collaborative component development and evaluation, working closely with customers and various stakeholders. As an illustration, the NIMC has recently recognized advanced thermal management as a potentially influential technology and is currently conducting an in-depth assessment of the challenges and subsystem sensitivities associated with this emerging thermal system technology. This proactive approach ensures that the NIMC remains at the forefront of technological advancements in the EV industry.

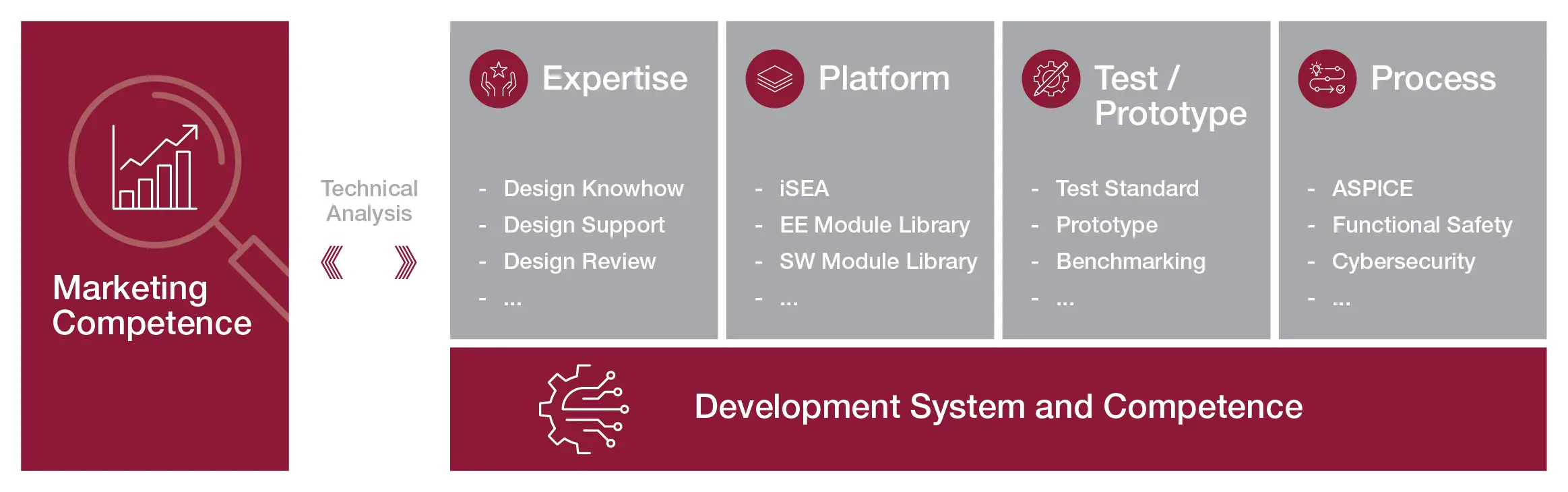

This work is enabled by a diverse team of experts in market intelligence, engineering, software development, product testing, and manufacturing is driving the establishment of development frameworks and competencies for the entire auto ecosystem. This includes design expertise, development toolkits, and processes. For instance, ITW’s Standard Electronic Application Platform (iSEA) ensures compatibility, reliability, and efficiency in smart component design and development. Additionally, the Automotive Software Process Improvement and Capacity Determination (ASPICE) process ensures adherence to industry best practices, resulting in high-quality code and reliable software. In a major step forward, the NIMC is expanding to 1500 m2 of office space and adding an 1800 m2 test laboratory, open in 2024.

ITW Automotive is in a unique position to look broadly across the industry to identify trends, risks and opportunities that will likely affect our customers. At the NEV Intelligent Mobility Center, we’ve assembled a team capable of seeing those trends as they’re developing, and rapidly engineering useful solutions for our customers that will increase the performance, quality and differentiation of their products.

The Center’s internal capabilities are enhanced by strategic partnerships. The NIMC sits at the hub of vehicle manufacturers and tier suppliers sharing knowledge, as well as leading industry institutions, consulting firms, and renowned universities in China. This extensive network enriches the collective knowledge and expertise of the NIMC and allows it to bring a broad market view and scale to its work.

As the automotive industry accelerates towards electrification, ITW Automotive’s NEV Intelligent Mobility Center is uniquely positioned to lead the way. To learn more about ITW Automotive’s NIMC and explore collaboration opportunities, please contact us.